TMT BAR Manufacturing Process

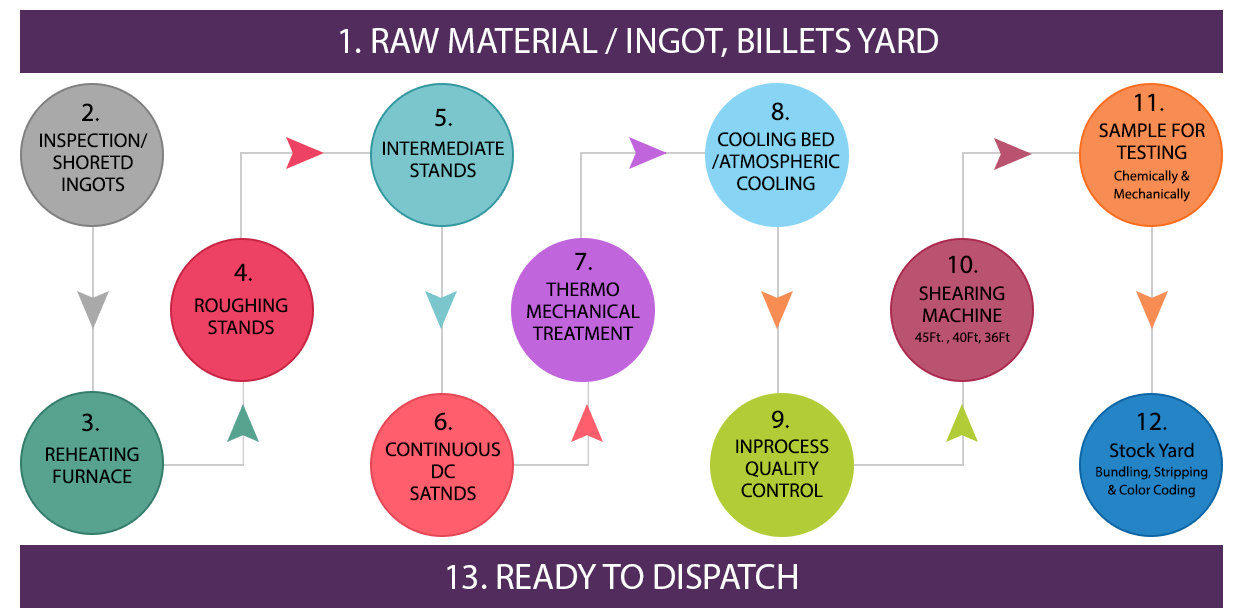

TMT bar stands for Thermo Mechanically Treated bar. In this process steel billets/ingots are heated in a reheating furnace and rolled through a sequence of rolling stands which progressively reduces the cross section of billets/ingots to the finished size and shape of the TMT reinforcement bar. This hot rolling process is followed by the quenching and self tempering process to give the bar more strength and ductility through three steps.

Quenching

A high pressure special water spray system is used on the hot rolled bar to turn its periphery into a martensite zone (hard zone) while keeping its inner surface ferrite perlite.

Self – Tempering

In this stage the bar leaves the quenching system with the temperature of the core being much higher than that of the surface. That makes heat to flow from the core to the surface, making the surface tempered, and a structure that is called “Tempered Martensite”.

Atmospheric Cooling

In this final stage, cooling takes place on the cooling bed where the final structure consists of hard outer periphery making it more stronger, more corrosion resistant and fire resistant. The soft inner surface gives the metal ductility (more bendability & elongation), and better fatigue resistance able to withstand natural calamities and other forces better.

The production of quality TMT bar depends on three major factors - quality of raw materials, a properly designed and automated mill, and a well-designed quenching the tempering technology and Sidhbali Industries is running on the same three factors. Due to this reason, SIDHBALI SARIA brand is the most qualitative brand in Indian Steel market.